Our engineering team collaborates with you to solve complex challenges. From material procurement to size adjustment, and finally to the development of precision components, our prototype to production mapping can simplify your project, combine innovation with industry, provide suitable components for your project, and help you achieve company goals.

Our network has sufficient capacity to meet any of your needs. Our global footprint allows for production and delivery as we offer suitable cost structures and component solutions. We consider the regional geopolitics and activities, economic effectiveness and social norms of these regions, as well as the technological advantages we can leverage.

We comprehensively utilize all of this information to develop products suitable for the region, producing products for customers at optimal cost and good quality.

Our lights out manufacturing factory provides precision CNC milling services to meet challenging requirements. Our equipment library includes 3, 4, and 5-axis milling machines, which are equipped with various efficiency enhancing features. We focus on milling small and medium-sized parts from prototypes to mass production.

By using robot automation and tool load checking to optimize tool life, we are able to produce high-precision complete parts. We operate over 75 CNC lathes between our two lean manufacturing factories located in the United States and China.

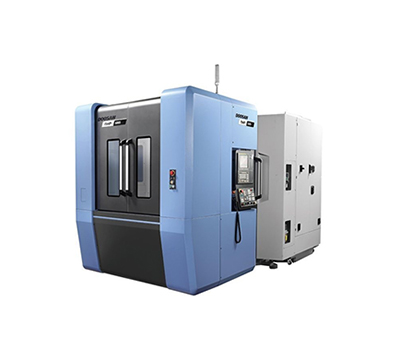

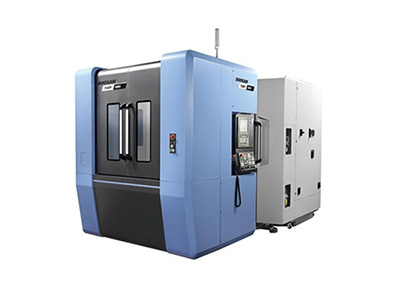

Our MMC2 system connects various horizontal machining centers with automated pallet systems to improve productivity. Through technology and innovation, the system provides built-in automation, light off production (LOOP), efficiency and flexibility, cost improvement, and reduces customer setup time.

A global manufacturer of hybrid electric vehicle motors has been recommended to Bracalente to help solve their motor installation issues with Chinese suppliers.

Accuracy≤0.01mm

CNC Horizontal Machining

Accuracy≤0.002mm

CNC Cylindrical Grinder

Accuracy≤0.003mm

Mind Machine

Accuracy≤0.02mm

Multi Axis Machine

Accuracy≤0.002mm

CNC Five Axis Machining

Accuracy≤0.003mm

CNC lathe

Accuracy≤0.005mm

CNC Machining Center

Accuracy≤0.003mm

CNC Milling Composite

Accuracy≤0.01mm

CNC Horizontal Machining

Accuracy≤0.002mm

CNC Cylindrical Grinder

Accuracy≤0.003mm

Mind Machine

Accuracy≤0.02mm

Multi Axis Machine

Accuracy≤0.002mm300mm

CNC Five Axis Machining

Accuracy≤0.003mm

CNC lathe

Accuracy≤0.005mm

CNC Machining Center

Accuracy≤0.003mm

CNC milling composite

Bracalen's professional project evaluation engineers will optimize the product structure for you

Customized for you