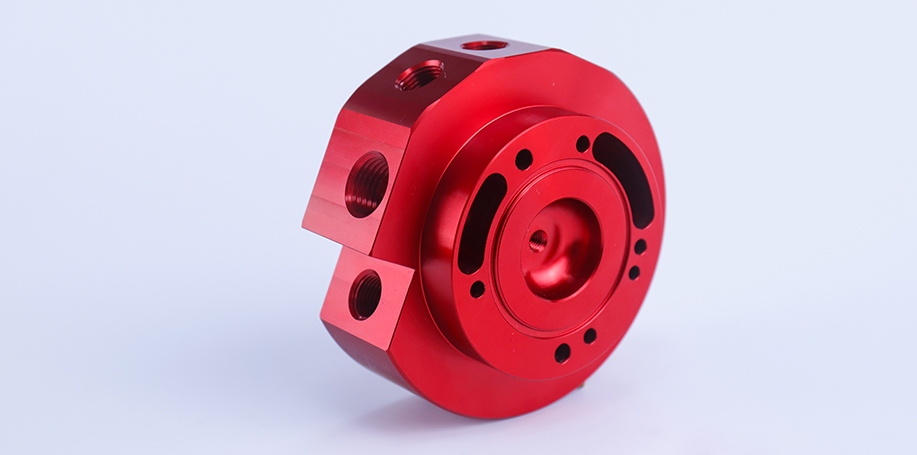

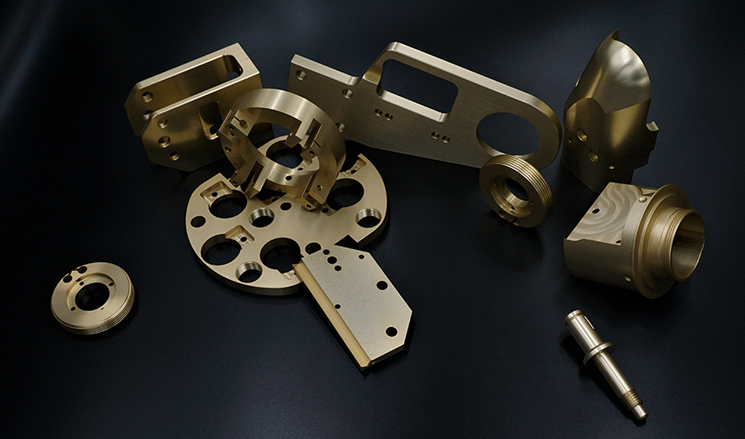

Friends who are familiar with precision machining know that hardware machining accounts for half of the precision parts and is also one of the common precision machining in daily life. So, what are the advantages of precision hardware machining?

1. Precision metal axis CNC machining has high precision and stable machining quality;

2. Can perform multi coordinate linkage and process complex shaped parts;

3. When precision hardware CNC machining parts change, generally only the CNC program needs to be changed, which can save production preparation time;

4. The machine tool itself has high precision and rigidity, and can choose favorable processing quantities, resulting in high productivity (generally 3 to 5 times that of ordinary machine tools);

5. The high degree of automation of machine tools can reduce labor intensity;

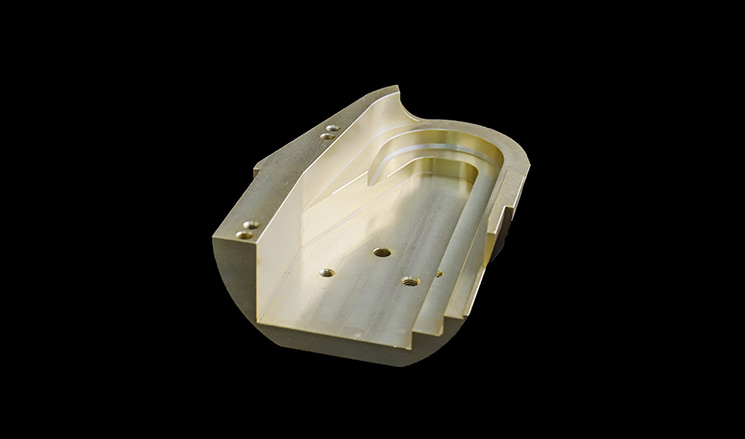

The use of short cutting tools in CNC precision machining is the main characteristic of precision hardware parts. Short tools can significantly reduce tool deviation, thereby achieving good surface quality, avoiding rework, reducing the use of welding rods, and shortening EDM processing time. When considering five axis machining, the goal of using five axis machining molds is to complete the entire workpiece machining with the shortest possible cutting tools, including reducing programming, clamping, and machining time while achieving better surface quality.

Tel

Tel Wechat

Wechat