We know that precision machining can be divided into standard part machining and non-standard part machining according to the machining object. Relatively speaking, standard part machining is relatively easy, while non-standard part machining is relatively more difficult. Many people do not distinguish between standard parts and non-standard parts.

Firstly, we know that non-standard parts are proposed relative to standard parts, so before understanding non-standard parts, we need to know what standard parts are. Standard parts refer to commonly used components that have been fully standardized in terms of structure, dimensions, drawing methods, markings, and other aspects, and are produced by professional factories, such as threaded parts, rolling bearings, and so on. Broadly speaking, it includes standardized mechanical parts such as fasteners, connectors, transmission components, seals, hydraulic components, pneumatic components, bearings, springs, etc. Narrowly defined, it only includes standardized fasteners. The commonly known standard component in China is the abbreviation for standard fasteners, which is a narrow concept, but the existence of a broad concept cannot be ruled out. In addition, there are industry standard parts, such as automotive standard parts, mold standard parts, etc., which also belong to general standard parts.

Non standard parts processing professionals mainly explain that the country has not established strict standard specifications, and there are no relevant parameter regulations for other accessories that are freely controlled by enterprises. There are many varieties of non-standard parts, and there is currently no standardized classification. The general classification is as follows:

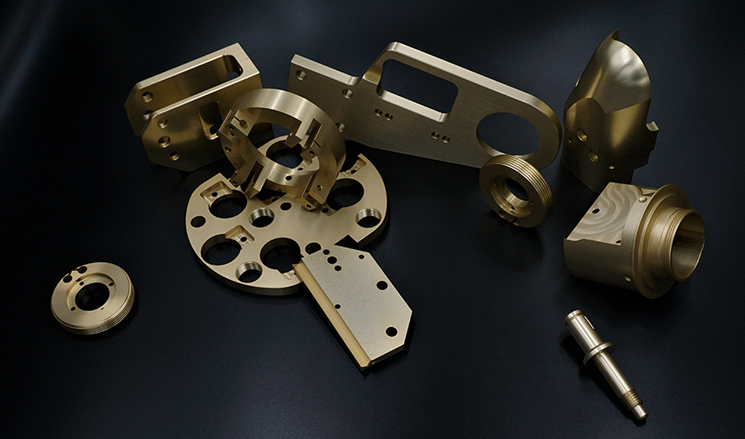

Metal non-standard parts:

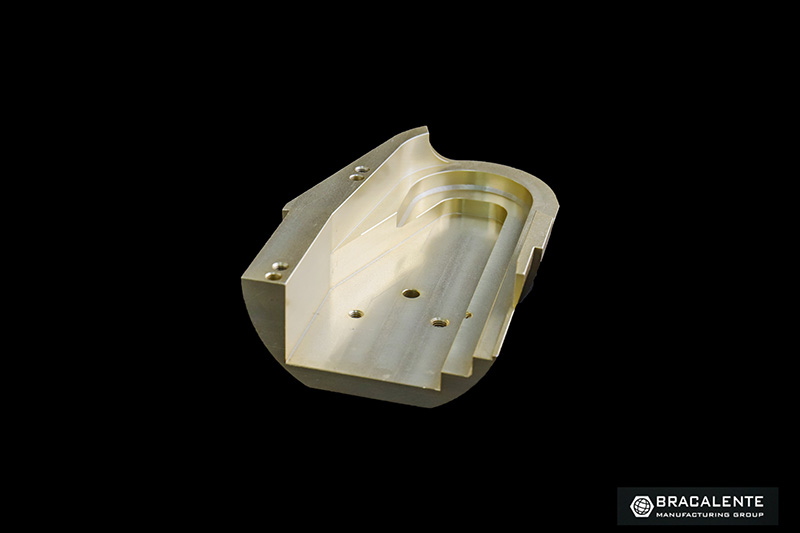

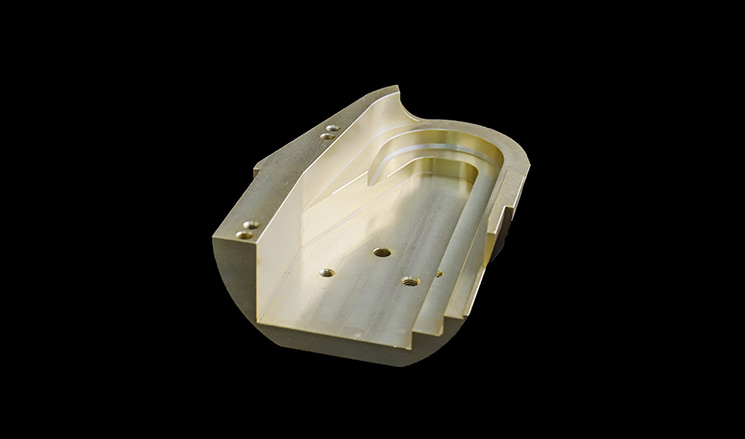

The customer provides the drawings, and the manufacturer uses the equipment to produce the corresponding products based on the drawings. Usually, the molds are mostly used, and the tolerance requirements and smoothness are specified by the customer, without a certain paradigm. The product requires corresponding quality control from casting to precision machining, with complex and variable processes, and generally higher costs than standard parts.

Non metallic and non-standard components:

It is the processing of some non-metallic materials. In recent years, the development of plastic molds in the injection molding industry, such as plastics, wood, and stone, has become increasingly sophisticated. The introduction of surface design and programming numerical control has greatly increased the cost and tolerance levels of non-standard processing.

Tel

Tel Wechat

Wechat