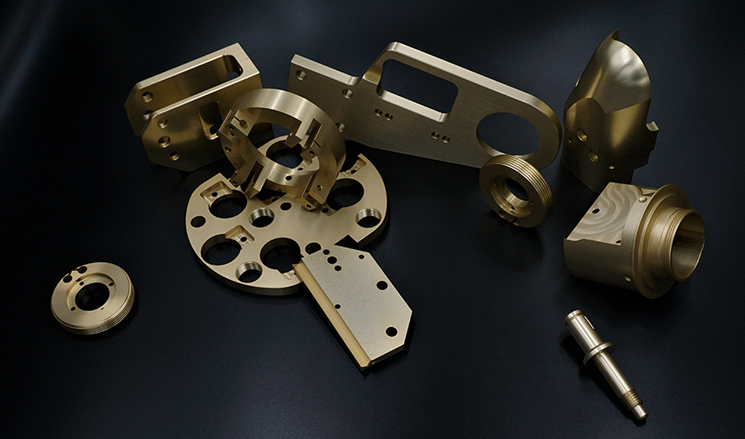

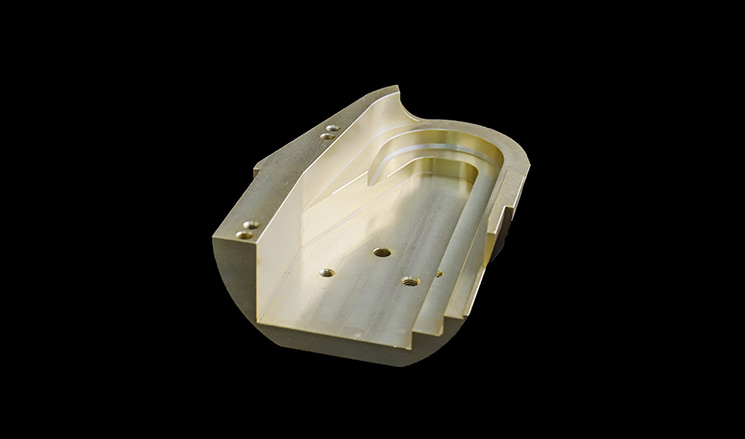

CNC lathe machining is a high-precision automated machine tool machining method that utilizes computer digital control technology to control the motion and machining process of the machine tool through pre programmed machining programs, achieving automated machining of workpieces. CNC lathe machining can process various complex shaped parts, with advantages such as high machining accuracy, high production efficiency, easy operation, and good repeatability. It is widely used in fields such as machinery, automobiles, aviation, and energy.

The main workflow of CNC lathe machining includes: analyzing part drawings and process documents, developing process plans and machining procedures, programming, program verification and trial cutting, setting the machining environment, machining process and quality inspection. Among them, programming is the core of CNC lathe machining, which requires writing the correct machining program based on part drawings and process requirements, controlling the movement and machining process of the machine tool.

CNC lathe machining has many advantages, such as high machining accuracy, high production efficiency, easy operation, and good repeatability. At the same time, it also has some limitations, such as restrictions on processing materials, high requirements for processing accuracy and surface quality, etc. Therefore, when choosing a CNC lathe for machining, it is necessary to comprehensively consider its advantages and disadvantages based on the actual situation and select a suitable machining method.

In short, CNC lathe machining is an important mechanical processing method that has become an indispensable part of modern manufacturing. For parts that require high-precision and complex shapes, CNC lathe machining is an ideal processing method.

Tel

Tel Wechat

Wechat